Comprehensive Lift Servicing Companies for Quick Lift Breakdown Repairs

Wiki Article

Thorough Analysis on Common Problems and Solutions in Lift Repair Service

In the realm of lift repair work, a thorough assessment of typical problems and their equivalent remedies is paramount to guaranteeing the smooth operation and security of these important vertical transportation systems. From the vexing issues with lift doors to the intricate complexities of electrical malfunctions, a myriad of obstacles can plague lift functionality (lift repair). As we explore the intricacies of lift maintenance, a thorough understanding of these problems and the efficient strategies for solving them becomes an essential aspect of making sure optimum lift efficiencyElevator Door Issues

One of the most usual obstacles come across in lift upkeep is addressing lift door malfunctions. The smooth procedure of elevator doors is vital for traveler security and efficiency. A defective door can result in delays, aggravation, and even prospective threats.Lift door concerns can come from numerous variables, such as defective door sensors, misaligned doors, worn-out rollers, or issues with the door driver device. These malfunctions can cause doors closed or shutting properly, getting stuck midway, and even shutting too swiftly, posing a danger to passengers getting in or exiting the lift.

To address lift door malfunctions efficiently, upkeep specialists must carry out regular assessments, lube moving parts, readjust door timings, and change worn-out elements without delay. Additionally, executing preventative upkeep schedules can help recognize and solve possible door concerns before they rise. By prioritizing elevator door upkeep and without delay dealing with malfunctions, structure proprietors can ensure the efficient and secure procedure of their lifts.

Electric Breakdowns

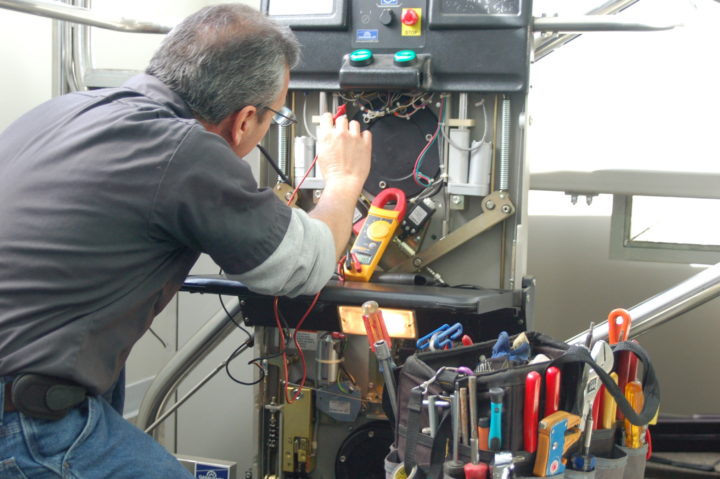

Dealing with electrical breakdowns in lifts calls for comprehensive diagnostic assessments and specific troubleshooting techniques to make sure the safe and dependable functioning of the lift system. Electric malfunctions can materialize in various methods within a lift system, varying from concerns with the control board, defective wiring, power supply issues, to problems with sensors and interlocks. When running into electric malfunctions, it is vital for maintenance workers to adhere to a methodical technique. This includes checking the power supply to the lift, evaluating wiring for any kind of indications of damages or wear, and evaluating the capability of crucial parts such as the control board and emergency situation quit button. Utilizing analysis devices such as multimeters and circuit testers can help in determining the source of the electric malfunction accurately. Furthermore, ensuring that all electric connections are safe and secure and up to code is important in avoiding future malfunctions. By dealing with electric concerns immediately and efficiently, lift service technicians can keep the safety and security and performance of lift procedures.Hydraulic System Problems

Furthermore, hydraulic pump failures can happen as a result of concerns such as getting too hot, extreme wear, or lack of proper upkeep. A malfunctioning pump can lead to the lift not being able to generate adequate hydraulic pressure to run efficiently. Regular inspection, upkeep, and prompt substitute of hydraulic components can prevent these issues and make certain the smooth performance of the lift system. Correct training for maintenance personnel on hydraulic system fixing and repair can additionally assist in attending to these issues promptly and effectively.

Control System Glitches

Control system malfunctions can interrupt the smooth operation of lift systems and pose security risks otherwise quickly dealt with. These glitches commonly stem from issues such as electrical failures, software pests, or sensing unit malfunctions. When the control system fails to connect properly with the lift parts, it can cause erratic movements, unexpected quits, or full closures. One common problem is the misalignment of sensors, causing unreliable floor progressing and door procedures. Electric failings, including power rises or harmed electrical wiring, can also trigger the control system to breakdown.To attend to control system glitches, lift repair work service technicians need to carry out extensive diagnostics to identify the root reason of the issue. By immediately attending to control system malfunctions, lift drivers can guarantee the security and integrity of their systems for guests and protect against expensive downtime.

Security Includes Problems

In making sure the optimum performance of lift lift repair systems, alertness in the direction of the integrity of safety and security functions ends up being critical adhering to the recognition and resolution of control system glitches. Safety attributes in lifts are developed to protect against accidents, injuries, and breakdowns. Typical concerns associating with safety and security features include issues with door sensors, emergency brakes, overload sensing units, and fire-rated landing doors. Door sensors are essential for finding blockages and guaranteeing doors do not shut on travelers. Emergency situation brakes are important for quiting the lift in case of a mechanical failure. Overload sensors aid prevent the lift from running when it surpasses its weight capability. Fire-rated landing doors are critical for having fires and safeguarding passengers during emergencies. Regular maintenance, examinations, and screening of these security functions are important to ensure they are operating properly. Attending to safety and security function worries promptly can dramatically reduce the danger of crashes and improve the overall safety of lift operations.Verdict

In verdict, typical problems in lift repair service consist of lift door issues, electrical breakdowns, hydraulic system problems, control system glitches, and safety attributes concerns. It check that is important for upkeep teams to attend to these concerns without delay to ensure the secure and efficient operation of elevators. By applying correct upkeep procedures and normal examinations, these issues can be determined and resolved efficiently to avoid any type of disturbances in lift function.

In ensuring the optimum performance of lift systems, alertness towards the integrity of security Check This Out functions comes to be paramount following the identification and resolution of control system glitches - lift service company.In conclusion, common issues in lift repair service include elevator door concerns, electric breakdowns, hydraulic system troubles, control system problems, and safety attributes concerns

Report this wiki page